Press Power Solutions

Expert Electrical Support

for Printing Equipment

When your press equipment goes down, every minute counts. At Pressroom Solutions, we specialize in fast, reliable electrical support for commercial printing and packaging equipment. Our expert technicians work efficiently to diagnose, repair, and upgrade your systems—minimizing costly downtime and keeping your production moving.

Comprehensive Electrical Services for Press Equipment

Our industrial electrical support includes:

Electrical Troubleshooting & Diagnostics

We locate and resolve complex electrical issues quickly using advanced diagnostics and deep knowledge of pressroom systems.

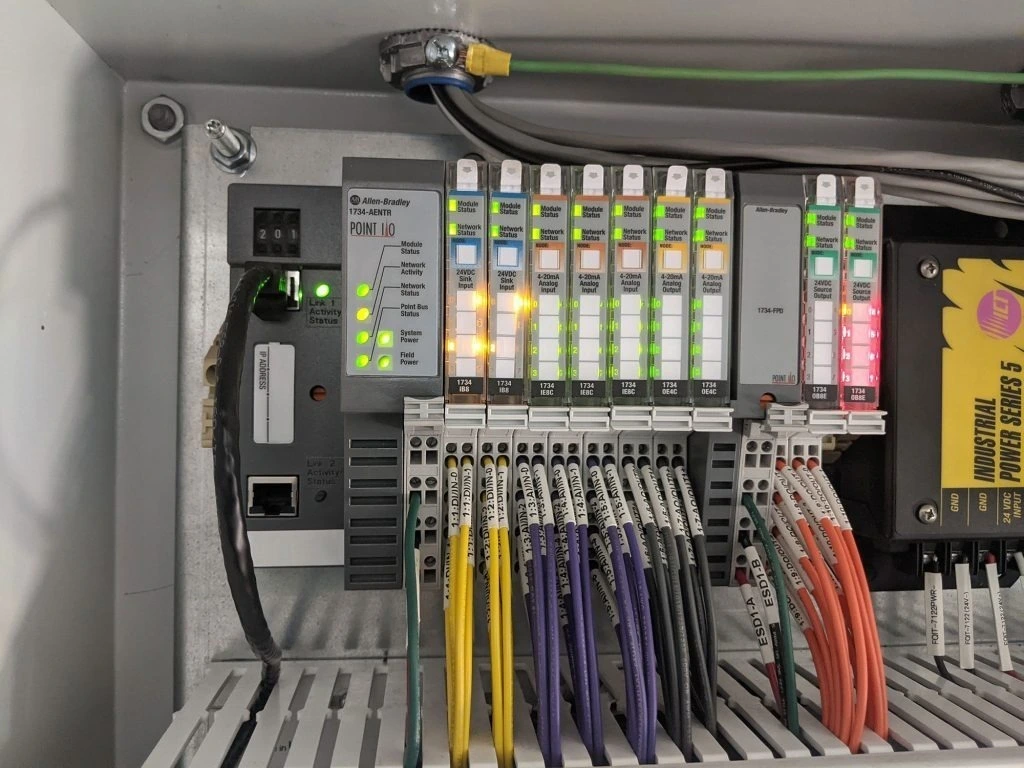

Control Panel Repairs & Upgrades

From legacy systems to modern PLC control panels and drive upgrades, we repair or retrofit your equipment to meet today's operational and safety standards.

Wiring, Rewiring & System Cleanup

Ensure safe, code-compliant installations with professional wiring or complete system rewiring—organized for long-term reliability.

Preventive Electrical Maintenance

Proactive inspections and service to avoid breakdowns before they happen, tailored to your equipment’s electrical requirements.

Emergency Electrical Support

We offer responsive service when you need it most—restoring your equipment with minimal disruption.